LY9TCR

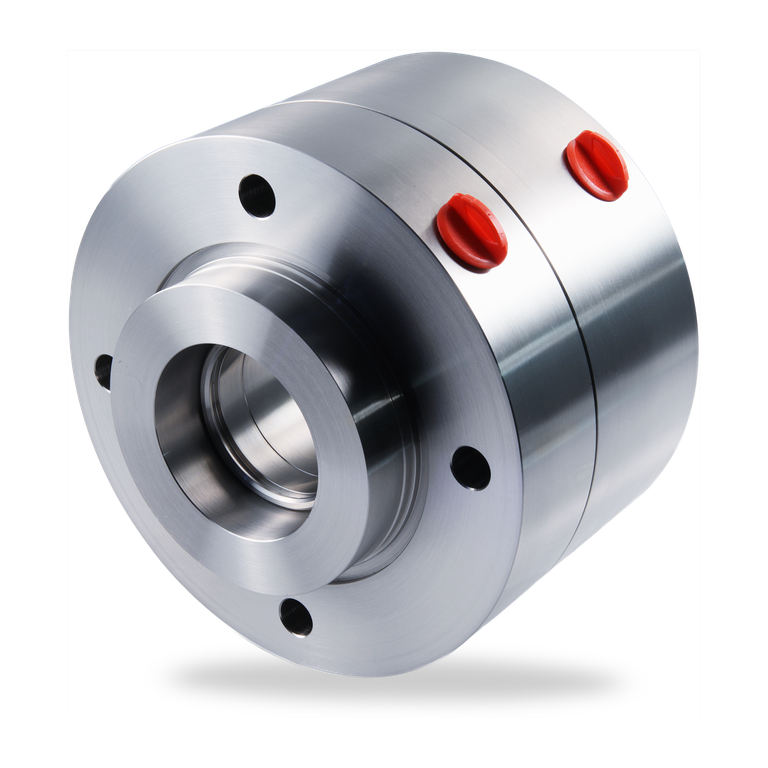

LY9TCR

LY9TCR-T

Dual seal

Arrangement: Face-to-back (Tandem),

2CW-CW, 3CW-FB

F Flush

LBO Liquid buffer/barrier OUT

LBI Liquid buffer/barrier IN

Dual seal

Arrangement: Face-to-back (Tandem),

2CW-CW, 3CW-FB

| Item | Description |

| 1,10 | Seal ring with bellows unit |

| 2, 3, 4, 6, 9, 12, 18 | Graphite ring |

| 5, 7, 14 | Set screw |

| 8, 17 | Mating ring |

| 11 | Assembly fixture |

| 13 | Driver with pumping screw |

| 15 | Adapter |

| 16 | Spiral wound gasket |

| 19 | Seal sleeve |

| 20 | Gland plate |

| 21 | Insert |

F Flush

LBO Liquid buffer/barrier OUT

LBI Liquid buffer/barrier IN

LY9TCR

Features

- API 682 Category 2 and 3, Type C seal

- Balanced

- Cartridge unit

- Rotating metal bellows

- Shrink fitted seal rings and solid mating rings

Advantages

- Compact design

- Also available in double ply design

- Suited for application with extreme high and low temperature

- Absence of dynamic O-ring eliminates/reduces seal face hang-up

- Bellows design minimizes variation in face load due to shaft expansion or face wear

- Resistant to abrasive particles in the medium, no shaft or sleeve fretting

Materials

Seal ring: Blister resistant carbon (C4), RBSiC (Q2)

Mating ring: RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seal: Graphite (G)

Metal parts: CrNiMo steel 316/316L (G), Carpenter® 42 (T4)

Mating ring: RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seal: Graphite (G)

Metal parts: CrNiMo steel 316/316L (G), Carpenter® 42 (T4)

Standards and approvals

- API 682 / ISO 21049

- API 682 4th ed. Cat. 2/3

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- LPG plants / Process pumps

- API 610 / ISO 13709 pumps

- CCUS

- Hydrogen

- Sustainable plastics production

- Alternative fuels production

Recommended piping plans

Process side (Dual seal / Single seal):

API Plan 01

API Plan 02

API Plan 03

API Plan 11

API Plan 12

API Plan 13

API Plan 14

API Plan 21

API Plan 22

API Plan 23

API Plan 31

API Plan 32

API Plan 41

Between seals (Dual seal):

API Plan 52

API Plan 53A

API Plan 53B

API Plan 53C

API Plan 54

API Plan 55

Atmospheric side (Dual seal):

API Plan 61

API Plan 62

API Plan 65A

API Plan 65B

Atmospheric side (Single seal):

API Plan 51

API Plan 61

API Plan 62

API Plan 65A

API Plan 65B

API Plan 66A

API Plan 66B

API Plan 01

API Plan 02

API Plan 03

API Plan 11

API Plan 12

API Plan 13

API Plan 14

API Plan 21

API Plan 22

API Plan 23

API Plan 31

API Plan 32

API Plan 41

Between seals (Dual seal):

API Plan 52

API Plan 53A

API Plan 53B

API Plan 53C

API Plan 54

API Plan 55

Atmospheric side (Dual seal):

API Plan 61

API Plan 62

API Plan 65A

API Plan 65B

Atmospheric side (Single seal):

API Plan 51

API Plan 61

API Plan 62

API Plan 65A

API Plan 65B

API Plan 66A

API Plan 66B

Product variants

LY9TCR-S

Single seal

Arrangement: 1CW-FL

Single seal

Arrangement: 1CW-FL

Similar products

LY9DTSS

- API 682 Category 2 and 3, Type B, Arrangement 2 and 3 seal

- Dual seal in face-to-back arrangement

- Same seal size of inboard and outboard seal

- Balanced

- Cartridge unit

- Rotating metal bellows

- Shrink fitted seal rings and solid mating rings

LY9DZSS

- API 682 Category 2 and 3, Type B, Arrangement 3 seal

- Dual seal in back-to-back arrangement

- Same seal size of inboard and outboard seal

- Balanced

- Cartridge unit

- Rotating metal bellows

- Shrink fitted seal rings and solid mating rings

LY9SA

- API 682 Category 2 and 3, Type B, Arrangement 1 seal

- Single Seal

- Balanced

- Cartridge unit

- Rotating metal bellows

- Shrink fitted seal ring and solid mating ring